DEFRO has a modern, computerized machine park, and the constantly expanded production offer results in systematic modernization and continuous expansion of production lines. These arguments allow for the implementation of many new achievements in the company’s achievements and a high level of services, and many years of experience in steel processing guarantee the quality of manufactured DEFRO devices. The production plant is equipped with, among others, several technological blocks such as:

DEFRO is not only a company with many years of experience in the industry, but also a leader in innovation and modern solutions in the production of heating devices. Our automated machinery and investments in robotization are the foundation of our success.

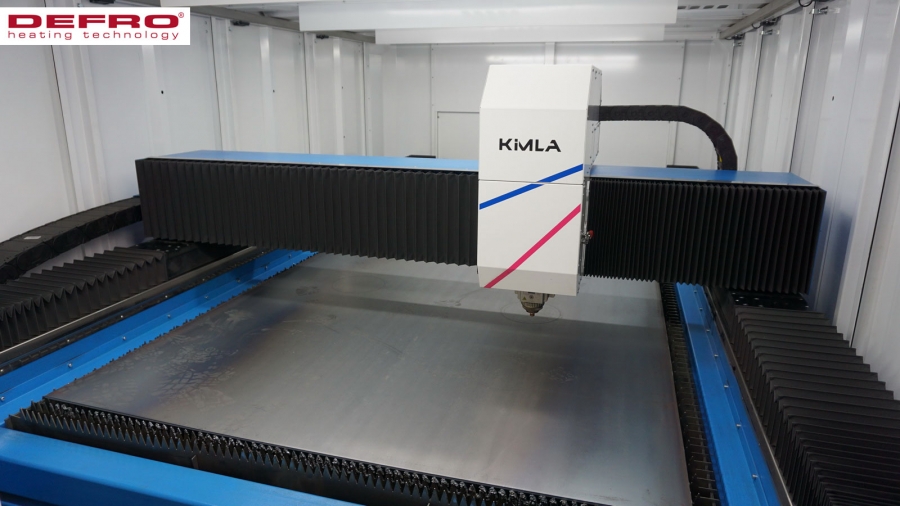

The latest technologies, such as laser cutting of sheet metal from renowned brands – Trumpf, Bystronic or Kimla, allow us to achieve the highest precision and quality of our products. However, this is only the tip of the iceberg.

An advanced, 3rd generation robotic welding socket guarantees the reliability and durability of our devices. The painting line with an automatic shot-blasting cabin ensures the durability of the coating, which is not only protection, but also the showcase of our products.

Our automatic powder coating lines are more than just a process – they guarantee an even and durable coating that meets the highest quality standards. In the machining center, we use the latest technologies, guaranteeing precision in manufacturing even the most complex construction elements.

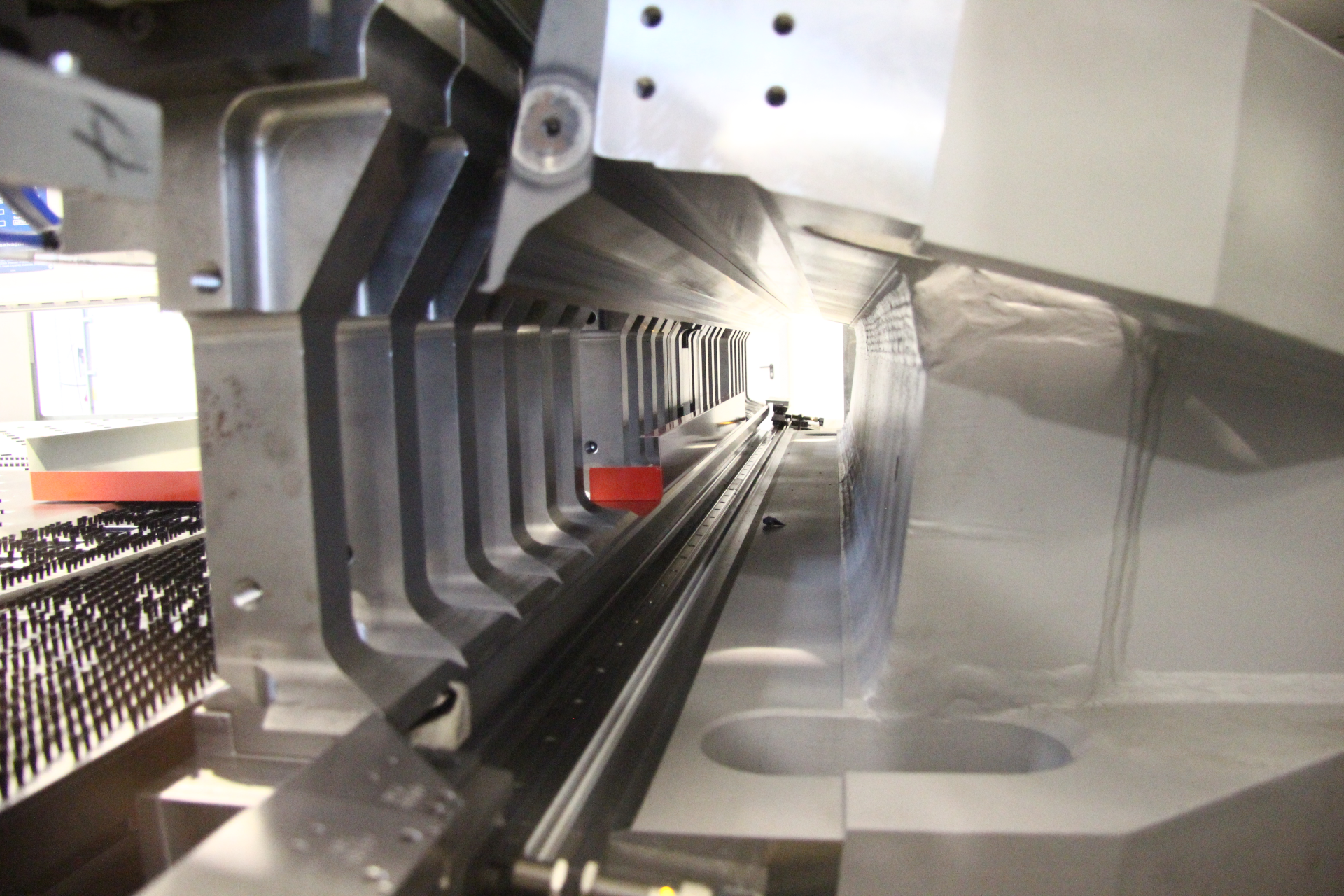

But it is not everything. Our CNC plastic processing center is a real stable of technological wonders. Press brakes, bending machines, four-roll rolling machines and numerically controlled punching machines enable comprehensive processing of elements, opening up almost unlimited possibilities in design and production.

The integrated cutting and bending line is another milestone in our production. A turret punching machine with a guillotine and a bending center are a dynamic duo that guarantees precision and speed of production, regardless of the scale and complexity of the order.

And this is only part of our advanced technological base. Our automated longitudinal and circumferential welding cell is another element that ensures that our products not only meet, but often exceed the highest quality standards.

We believe that investments in modern technologies are investments in the future of our clients. Our ability to constantly develop and innovate allows us to meet even the most sophisticated market expectations.

The industrial plant has several professional, fully equipped paint shops and shot-blasting rooms. These key infrastructure elements constitute the foundation for the production of high-quality industrial products.

Paint shops:

The company’s paint shops include specialized rooms equipped with the latest equipment. They have precise painting stations and professional ventilation systems, which guarantee excellent conditions for painting works. Thanks to the use of modern technologies, paint shops are able to ensure a durable and aesthetic finish of products.

Shot blasting plants:

The plant has both automated and standard shot blasting plants. These high-class devices enable surface treatment, removal of layers of rust and preparation of elements for further production processes. Thanks to the diversity of shot blasting plants, the plant is able to meet various customer requirements and specifications.

It is worth emphasizing that the highly qualified staff of the plant has not only specialist knowledge, but also experience in the operation of these advanced devices. Thanks to this, painting and shot-blasting processes are carried out with the highest precision and attention to the smallest detail. The whole thing is an integral element of ensuring the highest quality of manufactured industrial products.

Have more questions?

Would you like to ask about a discount?

Do you need device selection?

If you want to install a new heat source, it is worth paying attention to DEFRO devices, a Polish manufacturer with many years of experience in the heating industry. Our specialists will help you choose the right boiler and its power, and distributors and installers will take care of the assembly and commissioning, and all you need to do is enjoy the warmth and comfort. The distribution network of our products is divided into regions for which managers and salespeople are responsible.