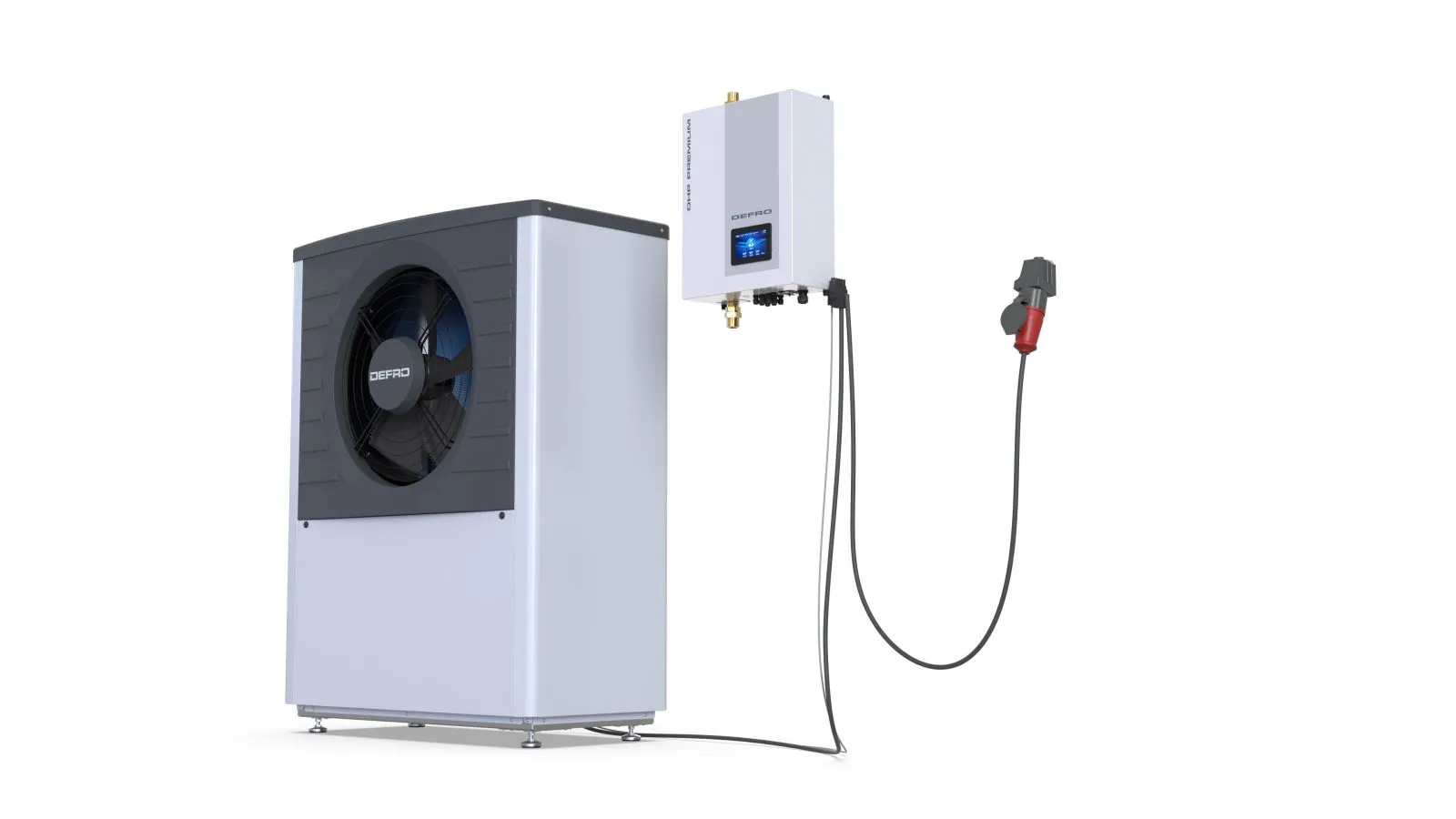

The electrical connection is extremely simple and quick. It comes down to connecting the external unit with the hydromodule using a dedicated cable supplied with the heat pump, and then plugging the hydromodule into the plug socket using a cable with a plug, also included in the set. This minimizes the risk of making errors when connecting and significantly shortens the assembly time.

DEFRO DHP PREMIUM is a monoblock air-water heat pump of the latest generation, created especially for Polish climatic conditions. Designed and manufactured in Poland by the largest manufacturer of heating devices with 100% domestic capital. The device was tested by scientists from AGH.

| Technical data | DHP PREMIUM 8 | DHP PREMIUM 12 |

|---|---|---|

| Heating power / COP przy A7 / W35* | 7,9 kW / 4,8 | 12,0 kW / 4,8 |

| Heating power / COP przy A2 / W35* | 6,1 kW / 3,8 | 9,0 kW / 3,8 |

| Heating power / COP przy A-7 / W35* | 5,4 kW / 3,5 | 7,6 kW / 3,2 |

| Heating power / COP przy A-15 / W35* | 4,5 kW / 2,9 | 7,0kW / 3,0 |

| Energy efficiency class (supply temperature 35oC) | A++ | A++ |

| Energy efficiency class (supply temperature 55oC) | A++ | A++ |

| Minimum / maximum temperature of the central heating circuit. and C.W.U. | 10oC / 65oC | 10oC / 65oC |

| Refrigerant / refrigerant mass | R290 / 1,2 kg | R290 / 1,4 kg |

| Compressor type | Copeland Scroll | Copeland Scroll |

| Lower / upper air temperature limit for pump operation | -25oC / + 35oC | -25oC / + 35oC |

| Sound power level outdoor / outdoor night mode / indoor | 59 / 43 dB (A) | 60 / 36 dB (A) |

| Supply voltage of the heat pump | 3×400 V, 50 Hz | 3×400 V, 50 Hz |

| Safeguard | C 20A | C 20A |

| Ground – outdoor unit | 209 kg | 215 kg |

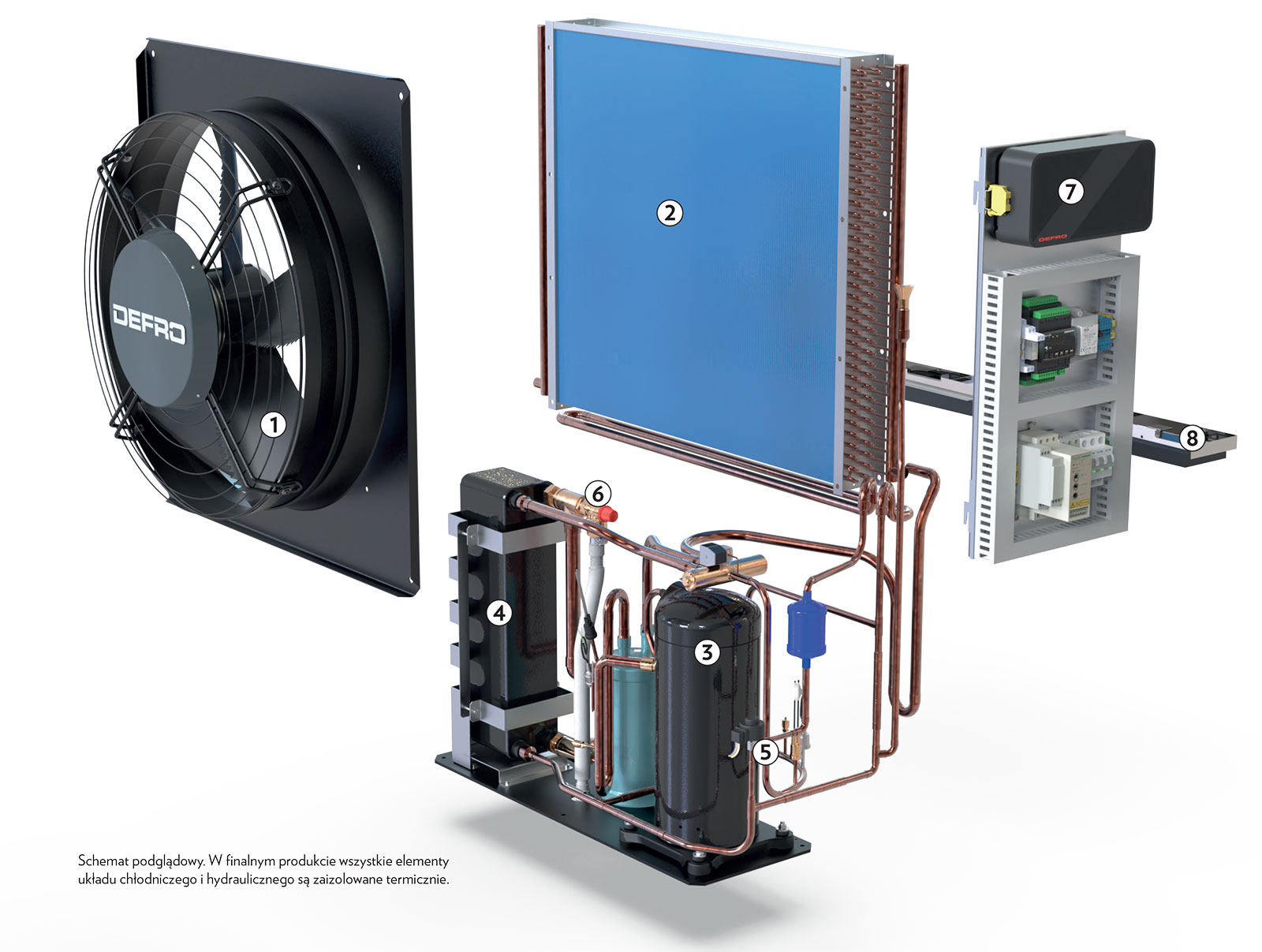

Jednostka wewnętrzna DHP PREMIUM HF (FULL) – kompletny zestaw z zaworem C.O./C.W.U.

1. Przyłącza elektryczne i czujniki,

2. Króciec zasilania z jednostki zewnętrznej,

3. Króciec powrotu do jednostki wewnętrznej,

4. Króciec zasilania C.O. i C.W.U.,

5. Króciec powrotu z obiegu C.W.U.,

6. Króciec powrotu z obiegu C.O.,

7. Kolorowy wyświetlacz zapewniający intuicyjny i łatwy dostęp do żądanych ustawień,

8. Metalowa obudowa hydromodułu,

9. Króciec odpływu z zaworu bezpieczeństwa,

10. Grzałka elektryczna 6 kW,

11. Pompa obiegowa zintegrowana z zaworem trójdrogowym, zaworem bezpieczeństwa i odpowietrznikiem automatycznym,

12. Przepływomierz,

13. Licznik energii elektrycznej,

14. Sterownik hydromodułu.

Have more questions?

Would you like to ask about a discount?

Do you need device selection?

If you want to install a new heat source, it is worth paying attention to DEFRO devices, a Polish manufacturer with many years of experience in the heating industry. Our specialists will help you choose the right boiler and its power, and distributors and installers will take care of the assembly and commissioning, and all you need to do is enjoy the warmth and comfort. The distribution network of our products is divided into regions for which managers and salespeople are responsible.